What Is the Difference Between a Potential Transformer and a Voltage Transformer

A concise explanation of the key differences between potential transformers and voltage transformers for electrical systems.

Read More

The life expectancy of a dry type transformer typically ranges from 30 years to over 40 years. This longevity depends on factors such as insulation class, design quality, environmental conditions, and maintenance practices.

With proper care and regular inspections, dry type transformers often outlast other transformer types, making them a reliable and cost-effective choice for many applications.

Insulation class and temperature rise rating determine a dry type transformer’s heat resistance and performance longevity. Classes 105, 150, 185, and 220 correspond to maximum temperatures (in °C) the insulation can withstand without degradation.

Temperature rise rating indicates the transformer’s temperature increase above ambient during operation. Higher insulation classes and lower temperature rises generally extend transformer life expectancy but increase costs.

Design quality, material selection, and manufacturing processes directly influence dry-type transformer life expectancy and performance efficiency.

Environmental conditions significantly impact dry-type transformer lifespan.

Loading characteristics and overload history determine a dry-type transformer’s life expectancy. Consistent operation at rated capacity results in normal wear. Frequent overloading shortens lifespan.

Overloads generate excessive heat, accelerating insulation degradation. Short-duration overloads have cumulative effects. Monitor loading patterns and avoid sustained overloads.

Load profile impacts transformer stress. Constant, steady loads are less stressful than frequent fluctuations or high inrush currents. Use higher capacity ratings for variable loads to provide safety margins.

Maintain detailed loading history records, including overload events. This data helps assess cumulative stress and predict potential issues.

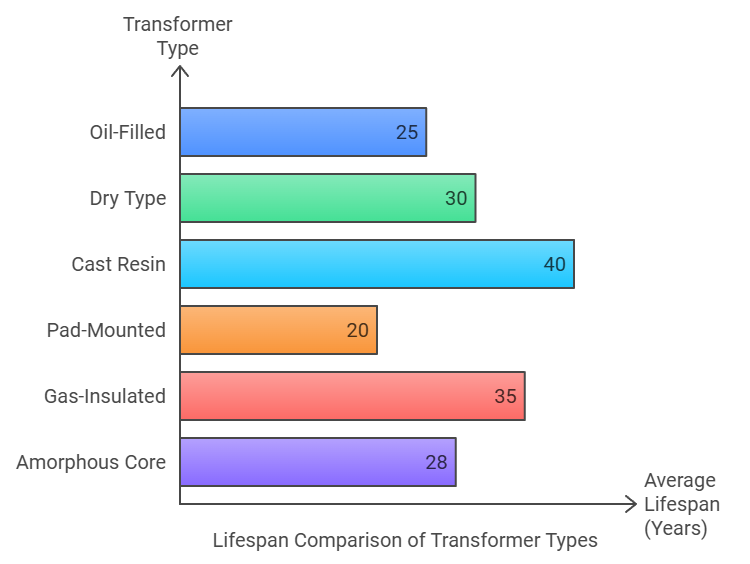

Dry type transformers outlast liquid-filled models. Oil-filled transformers typically operate for 20-30 years, while dry types often exceed 30 years with proper maintenance. The extended lifespan results from their simpler design and absence of liquid insulation, which can deteriorate over time.

Cast resin transformers, a dry transformer variant, can reach 40 years of service life. These units resist environmental factors better and need less upkeep than other types. Pad-mounted transformers, usually oil-filled, have a shorter 15-25 year lifespan due to outdoor exposure.

Gas-insulated transformers last 30-40 years but require specialized maintenance. Amorphous core transformers, available in dry or liquid-filled versions, may have slightly shorter lifespans due to their complex core structure. However, they offer improved energy efficiency during operation.

Dry type transformers can be repaired if damaged. Minor issues like loose connections or insulation problems are often fixable. However, extensive damage may necessitate replacement for safety and efficiency reasons.

Dry type transformers offer environmental benefits. They eliminate oil usage, reducing fire and spill risks. These transformers are more energy-efficient, quieter, and easily recyclable, making them an environmentally friendly option for power distribution systems.

Dry type transformers should undergo annual routine inspections. More frequent checks are necessary for harsh environments or heavy loads.

Dry type transformers have higher initial costs than oil-filled transformers due to specialized construction and materials. However, they often offer long-term savings in maintenance and installation expenses.

Dry type transformers can be used outdoors when properly protected. Weatherproof enclosures or shelters are typically employed. For severe environments, specially designed outdoor dry type transformers are recommended.