What Is the Difference Between Air Core and Ferrite Core

Air core and ferrite core are two types of cores commonly used in inductors and transformers. While both serve to concentrate and guide magnetic fields, they have distinct characteristics that make them suitable for different applications.

This article explores the key differences between air core and ferrite core, including their core material and structure, inductance, frequency response, size and weight, cost, and typical applications. By understanding these differences, engineers and designers can select the most appropriate core type for their specific requirements in electronic and electrical systems.

What Is Air Core

An air core, as the name suggests, is a type of inductor that does not use any magnetic material in its core. Instead, the coil is wound around a non-magnetic support structure, such as a plastic or ceramic form, with air filling the space inside the coil. The absence of a magnetic core material means that the inductance of an air core inductor is determined solely by the geometry of the coil, including its diameter, number of turns, and length.

Air core inductors have several advantages over their ferrite core counterparts. First, they have a linear inductance-current relationship, meaning that their inductance remains constant regardless of the current flowing through the coil. This linearity makes air core inductors ideal for applications that require a stable inductance value, such as in resonant circuits or filters.

Second, air core inductors have a low loss factor, which means that they have minimal energy dissipation in the form of heat. This low loss characteristic is due to the absence of a magnetic core material, which can introduce additional losses through hysteresis and eddy currents. As a result, air core inductors are well-suited for high-frequency applications where minimizing losses is crucial.

However, air core inductors also have some limitations. Due to the absence of a magnetic core, they typically have lower inductance values compared to ferrite core inductors of similar size. This means that air core inductors may require more turns or a larger coil diameter to achieve the same inductance value as a ferrite core inductor. Additionally, air core inductors are more susceptible to electromagnetic interference (EMI) since they lack the shielding properties provided by a magnetic core material.

What Is Ferrite Core

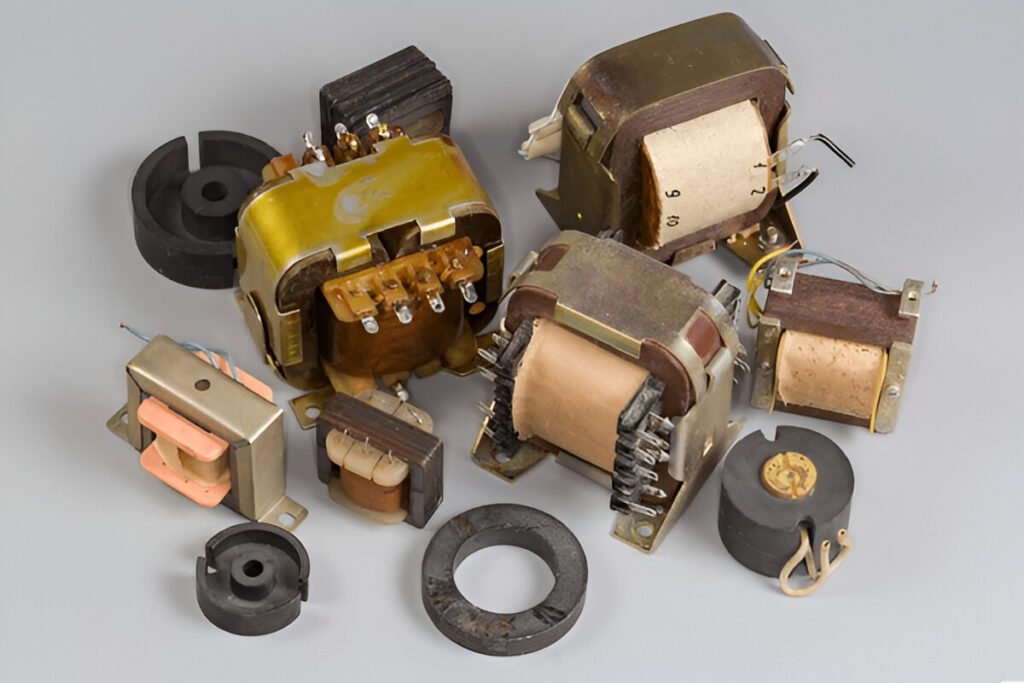

A ferrite core is a type of inductor that uses a magnetic ceramic material, called ferrite, as its core. Ferrite is a compound consisting of iron oxide combined with other metallic elements, such as manganese, zinc, or nickel. The ferrite core is placed inside the coil, and its magnetic properties significantly influence the inductor’s performance.

One of the primary advantages of ferrite core inductors is their ability to achieve high inductance values in a compact package. The magnetic properties of the ferrite material allow for a greater concentration of magnetic flux within the core, resulting in higher inductance values compared to air core inductors of similar size. This makes ferrite core inductors an attractive choice for applications where space is limited, and high inductance is required.

Ferrite core inductors also offer improved shielding against electromagnetic interference (EMI). The magnetic properties of the ferrite material help to confine the magnetic field within the core, reducing the inductor’s susceptibility to external EMI. This shielding property is particularly useful in environments with high levels of electromagnetic noise, such as in power electronics or communication systems.

However, ferrite core inductors also have some drawbacks. One limitation is their non-linear inductance-current relationship. As the current flowing through the inductor increases, the ferrite core begins to saturate, causing the inductance value to decrease. This non-linearity can be problematic in applications that require a stable inductance value over a wide range of currents.

Another disadvantage of ferrite core inductors is their higher loss factor compared to air core inductors. The ferrite material introduces additional losses through hysteresis and eddy currents, which can lead to increased energy dissipation in the form of heat. These losses become more pronounced at high frequencies, making ferrite core inductors less suitable for certain high-frequency applications.

Difference Between Air Core and Ferrite Core

Core Material and Structure

The primary difference between air core and ferrite core inductors lies in their core material and structure. Air core inductors have no magnetic material in their core, with the coil wound around a non-magnetic support structure and air filling the space inside the coil.

In contrast, ferrite core inductors use a magnetic ceramic material, called ferrite, as their core. The ferrite core is placed inside the coil, and its magnetic properties significantly influence the inductor’s performance.

Inductance

Ferrite core inductors typically achieve higher inductance values compared to air core inductors of similar size. The magnetic properties of the ferrite material allow for a greater concentration of magnetic flux within the core, resulting in higher inductance.

Air core inductors, on the other hand, have lower inductance values due to the absence of a magnetic core material. To achieve the same inductance value as a ferrite core inductor, an air core inductor may require more turns or a larger coil diameter.

Frequency Response

Air core inductors have a linear inductance-current relationship, meaning that their inductance remains constant regardless of the current flowing through the coil. This linearity makes air core inductors ideal for applications that require a stable inductance value, such as in resonant circuits or filters. Additionally, air core inductors have a low loss factor, making them well-suited for high-frequency applications where minimizing losses is crucial.

Ferrite core inductors, however, have a non-linear inductance-current relationship. As the current flowing through the inductor increases, the ferrite core begins to saturate, causing the inductance value to decrease. This non-linearity can be problematic in applications that require a stable inductance value over a wide range of currents. Moreover, ferrite core inductors have a higher loss factor compared to air core inductors, particularly at high frequencies, due to additional losses through hysteresis and eddy currents.

Size and Weight

Ferrite core inductors offer the advantage of achieving high inductance values in a compact package. The magnetic properties of the ferrite material allow for a greater concentration of magnetic flux within the core, enabling smaller inductor sizes for a given inductance value.

Air core inductors, lacking a magnetic core, may require larger coil diameters or more turns to achieve the same inductance as a ferrite core inductor, resulting in a larger overall size and weight.

Cost

Air core inductors tend to be less expensive than ferrite core inductors due to their simpler construction and the absence of a magnetic core material.

Ferrite core inductors, with their additional core material and potentially more complex manufacturing process, may have a higher cost compared to air core inductors of similar specifications.

Applications

Air core inductors are well-suited for applications that require a stable inductance value, low loss, and high-frequency operation. They are commonly used in resonant circuits, filters, and high-frequency communication systems. Due to their linear inductance-current relationship and low loss factor, air core inductors are ideal for applications where maintaining a constant inductance and minimizing energy dissipation are crucial.

Ferrite core inductors, on the other hand, are preferred in applications where high inductance values are required in a compact package, and where improved shielding against electromagnetic interference (EMI) is necessary. They are commonly used in power electronics, such as in switch-mode power supplies, DC-DC converters, and EMI filters. Ferrite core inductors are also used in low-frequency applications where their non-linear inductance-current relationship and higher loss factor are less problematic.