The Hangzhou-Wenzhou high-speed railway is an important transportation line connecting Hangzhou and Wenzhou, which is of great significance to the regional economic development and improvement of people’s livelihood. In order to ensure the stable and reliable power supply of the high-speed railway line, the Hangzhou-Wenzhou high-speed railway project started the construction of 8*800KVA box-type substations. ROOQ Electric Group Co., Ltd. (hereinafter referred to as “ROOQ Electric”) successfully won the bid for the project with its outstanding technical strength and rich project experience.

Project Overview

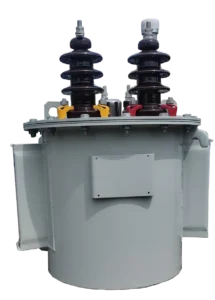

The 8*800KVA box-type substation project includes 8 800KVA box-type substations, which are designed to provide stable power support for the Hangzhou-Wenzhou high-speed railway. The main tasks of the project include equipment design, manufacturing, installation and commissioning. ROOQ Electric is responsible for the following work:

- Equipment design: According to the special needs of the high-speed railway project, design a box-type substation that meets high standards.

- Manufacturing process: Use advanced production technology and strict quality control to ensure the high performance and high reliability of the equipment.

- Intelligent control: Configure an intelligent monitoring system to achieve remote monitoring and management of the substation.

Equipment manufacturing and quality inspection

ROOQ Electric manufactures and controls equipment in strict accordance with international standards in its modern production plant:

- Material selection: High-quality steel and anti-corrosion materials are used to ensure the durability of the equipment in various environments.

- Advanced technology: The latest manufacturing technology and equipment are used to ensure the accuracy and consistency of the product.

- Comprehensive quality inspection: Each box-type substation undergoes strict quality inspection before leaving the factory to ensure that there are no defects and faults.

Product Packing

In order to ensure that the equipment is not damaged during transportation, ROOQ Electric has taken a series of strict measures during the packing process:

Professional packaging: Design a special packaging plan according to the equipment specifications, and use shock-proof, moisture-proof and dust-proof packaging materials.

Firm fixation: Use foam pads and straps in the packaging box to fix the equipment to prevent movement and collision during transportation.

Clear identification: Each packaging box is affixed with detailed labels on the outside, indicating the equipment name, specification model, quantity, weight and destination information to ensure the accuracy of loading and unloading and inspection.

Shipping process

After the equipment is packed, ROOQ Electric strictly follows the following process for shipment:

- Item inventory: Before shipment, the staff will count and check all equipment to ensure that the quantity and specifications are correct.

- Sealing and reinforcement: The packaging box is sealed and reinforced with steel belts to ensure that the packaging box is not easy to crack or deform during transportation.

- Logistics arrangement: Cooperate with professional logistics companies to develop detailed transportation plans and arrange suitable transportation tools to ensure that the equipment is delivered to the project site on time and safely.

Customer Service

ROOQ Electric attaches great importance to customer service and provides comprehensive technical support and after-sales service after the equipment is shipped:

- On-site installation: dispatch professional technicians to the site to install and debug the equipment to ensure the normal operation of the substation.

- Training support: provide customers with equipment operation and maintenance training to help customers better use and manage the equipment.

- After-sales service: establish customer files, make regular return visits, and promptly solve problems encountered by customers during use to ensure the long-term stable operation of the equipment.

Conclusion

ROOQ Electric Group Co., Ltd.’s successful implementation in the 8*800KVA box-type substation project of the Hangzhou-Wenzhou High-speed Railway once again demonstrated its leading technology and professional services in the field of electrical equipment manufacturing. Through strict production management, careful product packaging and thoughtful customer service, ROOQ Electric provides a solid power guarantee for the smooth operation of the Hangzhou-Wenzhou High-speed Railway.