Distribution Transformer Losses Calculation

Learn how to calculate power losses in distribution transformers due to load and no-load factors.

Read More

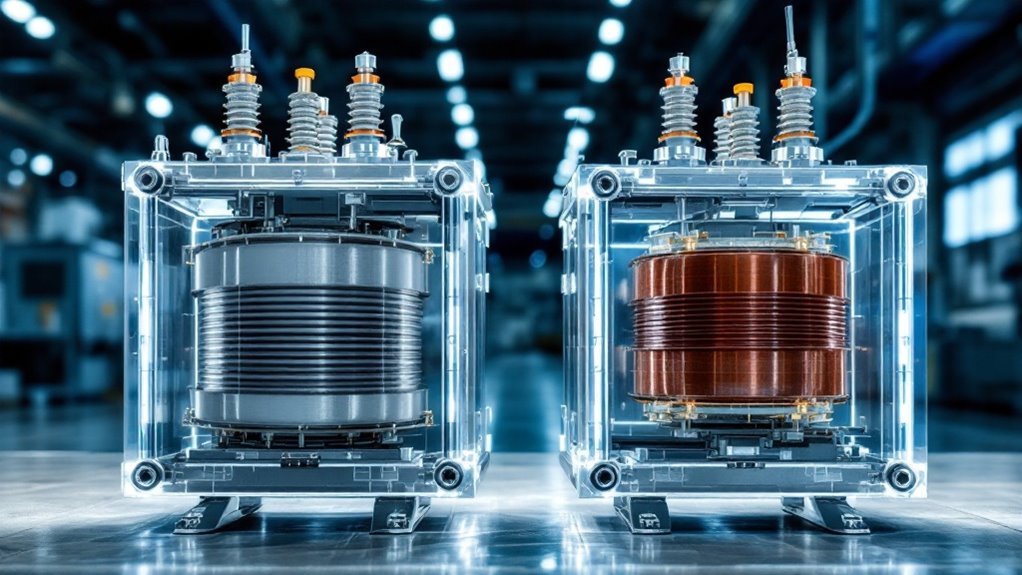

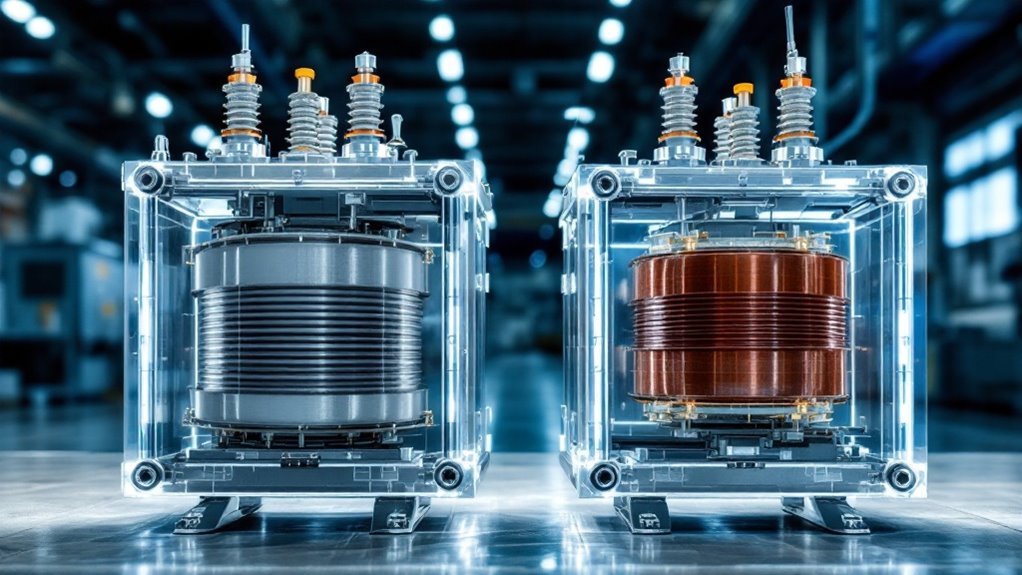

Have you ever wondered why dry-type transformers are becoming increasingly popular in modern buildings and facilities? The transformer core, often called the “heart” of the transformer, plays a decisive role in its performance and safety. Today, let’s dive into the differences between the dry-type transformer core and other types of cores, helping you better understand its advantages and application scenarios. Whether you are a power engineer, a procurement manager, or simply interested in transformers, this article will provide you with practical knowledge and selection tips.

Dry-type transformer cores are mainly made from high-quality silicon steel laminations, which offer excellent magnetic permeability and low losses. Some high-end products even use amorphous alloy materials, which can significantly reduce energy loss.

The core structures typically include:

Additionally, the surface of dry-type transformer cores is usually treated with special insulation to ensure interlayer insulation, prevent short circuits, and increase safety and durability.

| Feature | Dry-Type Transformer Core | Oil-Immersed Transformer Core |

|---|---|---|

| Insulation & Cooling | Air or solid insulation, cooled by natural or forced air | Immersed in transformer oil, which insulates and cools |

| Safety | Oil-free design, fireproof and explosion-proof, ideal for indoor high-safety areas | Risk of oil leakage and fire |

| Application | Shopping malls, hospitals, data centers, high-rise buildings (indoor) | Outdoor substations, large power plants |

| Maintenance Cost | Maintenance-free or low maintenance, low long-term operating cost | Requires regular inspection and oil replacement, higher maintenance cost |

In short, the oil-free design of dry-type transformer cores makes them more environmentally friendly and safer—especially for locations with high safety and environmental requirements. In contrast, oil-immersed transformers, while offering excellent cooling, come with potential environmental and safety risks.

You might be wondering: “Can a dry-type core really save energy?” The answer is yes! Dry-type transformer cores use highly magnetic materials and advanced structural designs, significantly reducing eddy current and no-load losses. Products with amorphous alloy cores can reduce no-load losses by up to 70%.

Other impressive technical innovations include:

These technical advantages make dry-type transformer cores not only efficient but also reliable in complex environments.

Different core structures suit different applications. Understanding them helps you make smarter choices:

Choosing the right dry-type transformer core comes down to your actual needs. Here are some tips:

When searching and comparing, you can use long-tail keywords such as “dry-type transformer core for data center” or “energy-efficient dry-type transformer core” to help refine your choices.

With their safety, eco-friendliness, and efficiency, dry-type transformer cores are quickly becoming the top choice in modern power systems. Whether you’re building a data center, hospital, or high-rise, choosing the right dry-type core can provide reliable assurance and long-term value for your project.

If you want to learn more about dry-type transformer cores or need a customized solution, feel free to contact us. Let’s work together to build a strong “heart” for your power system!

A dry-type transformer core is the magnetic core used in transformers that do not use oil for insulation or cooling. Instead, they rely on air or solid insulation and are cooled by natural or forced air.

High-quality silicon steel laminations are most commonly used. Some advanced dry-type transformer cores use amorphous alloy materials for even lower energy losses.

They are ideal for indoor environments with high safety and environmental requirements, such as shopping malls, hospitals, data centers, and high-rise buildings.

Yes! Thanks to advanced materials and innovative core designs, dry-type transformer cores can significantly reduce energy losses, especially when using amorphous alloys.

They require little to no maintenance compared to oil-immersed transformers, making them a cost-effective choice for long-term operation.